Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

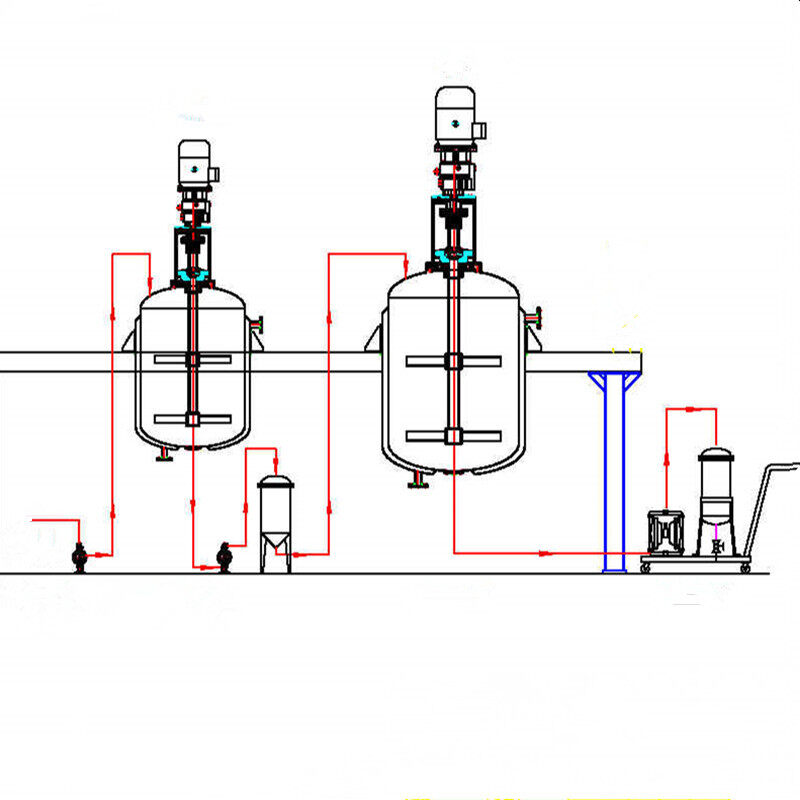

Process Flow of Coatings Production Line

water based noise reduction coatings production line

The process flow of the coating production line is divided into pretreatment, powder spraying, heating, and curing.

Early production

There are manual simple processes and automatic pre-treatment processes before treatment, and the latter is divided into automatic spray and automatic immersion spray. Before powder spraying, the workpiece must undergo surface treatment to remove oil and rust. In this section, more liquid is used, mainly including rust remover, oil remover, surface conditioner, phosphating agent, etc.

In the pretreatment section or workshop of the coating production line, the first thing to pay attention to is to develop necessary systems for the purchase, transportation, storage, and use of strong acids and bases, provide workers with necessary protective clothing, safe and reliable packaging, handling and configuration of equipment, and formulate emergency treatment measures and rescue measures in case of accidents. Secondly, in the pretreatment section of the coating production line, there are a certain amount of waste gas, waste liquid and other three wastes, so in terms of environmental protection measures, air extraction and exhaust, liquid discharge and three wastes treatment devices must be configured.

The quality of pretreated workpieces should be different due to the different process flow of pretreatment solution and coating production line. The oil and rust on the surface of the workpiece with good treatment shall be removed. In order to prevent rusting again in a short time, phosphating or passivation shall be carried out in several processes after the pretreatment. Before powder spraying, the phosphated workpiece shall also be dried to remove the surface moisture. Small batch single piece production generally adopts natural air drying, sun drying and air drying. For mass flow process, low temperature drying is generally adopted, and oven or drying channel is adopted.

Organize production

For small batch of workpieces, manual powder spraying device is generally adopted, while for large batch of workpieces, manual or automatic powder spraying device is generally adopted. Whether it is manual spraying or automatic spraying, it is very important to control the quality. Ensure that the sprayed workpiece is evenly powdered and has the same thickness, and prevent defects such as thin spraying, missing spraying, wiping off, etc.

During the leading process of the coating production line, attention should also be paid to the hook part of the workpiece. Before entering the curing process, the powder attached to the hook should be blown off as much as possible to prevent the excess powder on the hook from curing. If it is really difficult to remove the residual powder before curing, the cured powder film on the hook should be peeled off in time, so as to ensure that the hook is conductive well, so that the next batch of workpieces are easy to be powdered.

Curing process

Matters needing attention in this process include: if the sprayed workpiece is produced in a small batch, pay attention to prevent the powder from falling before entering the curing furnace. If there is any powder wiping phenomenon, timely spray the powder. Strictly control the process, temperature and time during baking, and pay attention to prevent insufficient curing caused by color difference, over baking or too short time.

For large quantities of automatically transported workpieces, it is also necessary to carefully check whether there is missing spraying, thin spraying or local powdering before entering the drying channel. If unqualified parts are found, they should be properly controlled to prevent them from entering the drying channel, and they should be removed for re spraying as far as possible. If some workpieces are unqualified due to thin spraying, they can be re sprayed and cured again after curing out of the drying channel.

The so-called coating refers to the covering of protective layer or decorative layer on metal and non-metal surfaces. The coating production line has experienced the development process from manual production line to automatic production line. The degree of automation is getting higher and higher, so the application of coating production line is becoming more and more extensive, and goes deep into many fields of the national economy.

Searching for a water based noise reduction coatings production line China, water based coatings production line, noise reduction coatings production line from China, you can get high-quality products at a nice price.