Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

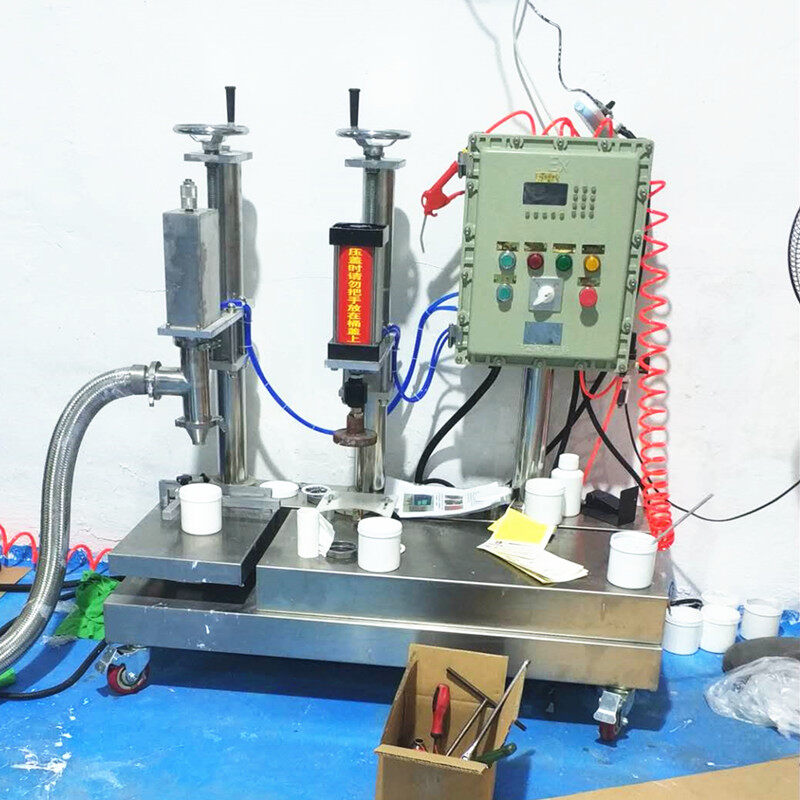

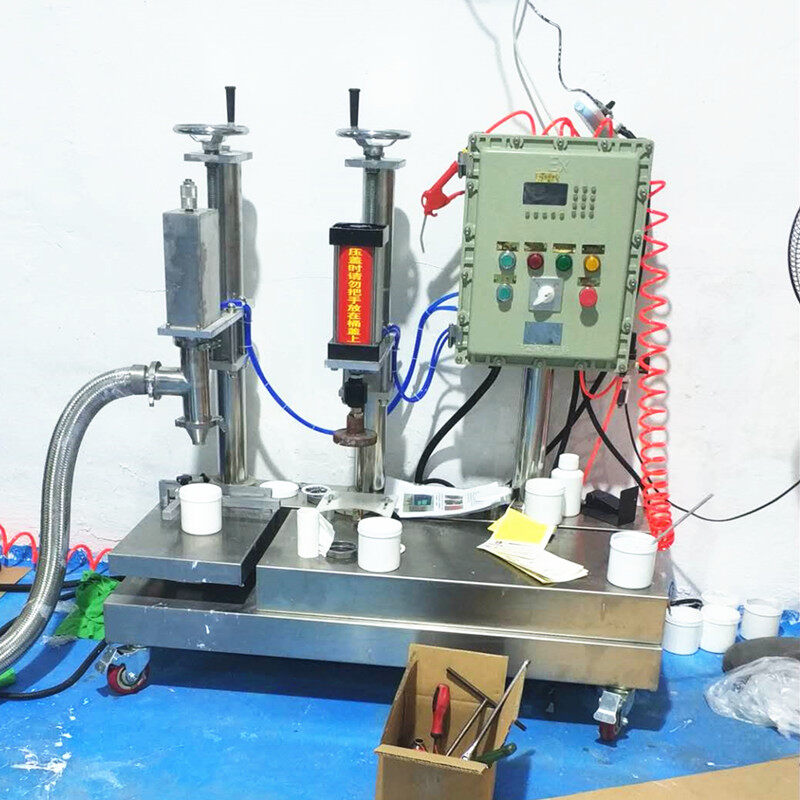

Understanding the Benefits and Features of a 1-5L Filling Machine for Efficient Production

In the fast-paced world of manufacturing and packaging, efficiency is key. Companies across various industries—from food and beverage to cosmetics—are always looking for ways to optimize their production lines. One of the essential pieces of equipment that plays a crucial role in this process is the 1-5L filling machine. This versatile machine is designed to streamline the packaging process, ensuring that products are filled accurately and efficiently. In this blog post, we will dive deep into the features, benefits, and applications of a 1-5L filling machine while also exploring how it compares to other filling machines, including those used for smaller capacities like 50ml-1000ml.

What is a 1-5L Filling Machine?

A 1-5L filling machine is a specialized piece of equipment used to fill containers with liquid or semi-liquid products. This machine is particularly popular in industries that need to package products in medium-sized containers, typically ranging from 1 liter to 5 liters in capacity. Whether you're dealing with water, juice, sauces, oils, or other liquid goods, the 1-5L filling machine ensures consistency, speed, and precision in the filling process.

Key Features of a 1-5L Filling Machine

Understanding the features helps businesses make informed decisions about which equipment best suits their needs. Here are the primary features you should know:

1. Adjustable Filling Range

One of the standout features is its adjustable filling range. Manufacturers can easily set the machine to accommodate a variety of container sizes within the 1 to 5-liter range. This flexibility is particularly useful for companies that deal with a wide range of product packaging sizes.

2. High-Speed Operation

Efficiency is key in any production line, and the machine is designed to operate at high speeds, allowing companies to fill large volumes of liquid products in a short amount of time. Depending on the model, some machines can fill dozens of containers per minute, which significantly reduces downtime and increases production capacity.

3. Accurate Filling Mechanism

For companies dealing with high-value products or industries where consistency is crucial, accuracy is non-negotiable. The machine uses advanced technology to ensure that each container is filled with the exact amount of product, minimizing waste and reducing the likelihood of customer complaints.

4. Ease of Cleaning and Maintenance

Given that many industries, particularly in food and beverage, require high hygiene standards, the machine is designed for easy cleaning and maintenance. The machine typically features components that can be quickly disassembled for cleaning, and it often uses materials that are resistant to corrosion, ensuring long-term durability.

5. Versatility

While some filling machines are designed for very specific product types, the machine can handle a wide variety of liquid and semi-liquid products. Whether you’re filling oils, sauces, shampoos, or detergents, this machine can be adjusted to handle the viscosity and flow characteristics of each product.

Comparing the 1-5L Filling Machine to Other Machines

When it comes to filling machines, size matters. A 50ml-1000ml filling machine might be suitable for smaller containers like cosmetic bottles or small beverage containers, but what happens when your production line needs to handle medium-sized containers? This is where the machine comes into play.

Small vs. Medium Filling Machines

-

50ml-1000ml Filling Machines: These machines are typically used for products that are packaged in smaller containers. They are ideal for industries such as cosmetics, pharmaceuticals, and specialty food products. These machines are designed for precision in smaller volumes, and they excel in environments where small container filling is the norm.

-

1-5L Filling Machines: The 1-5L filling machine is more suited for medium-sized containers. It’s ideal for packaging beverages, cleaning products, and other liquid products that require a larger volume than those handled by the 50ml-1000ml filling machine. These machines are built to handle larger volumes, making them suitable for industries that require higher output but still need to maintain filling accuracy.

Benefits of a 1-5L Filling Machine for Your Business

The right filling machine can make all the difference in streamlining production and reducing operational costs. Let’s explore how a machine can benefit your business.

1. Increased Production Efficiency

The machine is designed for high-speed operation, ensuring that you can fill hundreds or even thousands of containers in a single day. This high throughput translates into more product filled per unit of time, making your production line faster and more efficient. This is especially beneficial for businesses with high-demand products that need to be packaged quickly.

2. Cost-Effective

While the initial investment in a machine might be significant, the long-term savings are substantial. By automating the filling process, you reduce labor costs, minimize human error, and optimize your production line, leading to lower overall production costs. Additionally, the accuracy of the machine helps reduce product waste, further improving cost-effectiveness.

3. Flexibility in Packaging

Whether you need to fill 1-liter bottles, 5-liter jugs, or anything in between, the machine offers the flexibility to handle a range of container sizes. This is particularly useful for businesses that package products in different sizes to meet varying customer needs.

4. Consistency and Accuracy

In industries like food and beverage, consistency is vital. A machine ensures that every container is filled with the exact amount of product, preventing underfills or overfills that could lead to product loss or customer dissatisfaction. The machine’s precision reduces errors, ensuring that every batch is identical.

5. Reduced Labor Requirements

With the machine, businesses can significantly reduce the number of workers required for manual filling. This is particularly important in industries where labor shortages are a concern. Automation also frees up staff to focus on other important tasks, enhancing overall productivity.

Applications of the 1-5L Filling Machine

A 1-5L filling machine is a versatile piece of equipment that finds applications in various industries. Here are some common sectors that use this machine:

1. Food and Beverage

The food and beverage industry is one of the largest users of filling machines. Whether it's juices, sauces, milk, or oils, a 1-5L filling machine is essential for efficiently packaging liquid products into larger containers for retail or bulk distribution.

2. Chemicals and Detergents

For products like detergents, cleaning solutions, and industrial chemicals, the machine is the ideal solution. It can handle the varying viscosities of chemicals and ensure that containers are filled precisely without spills or overflows.

3. Cosmetics and Personal Care

While many cosmetic products are packaged in smaller containers, some items such as lotions, shampoos, and body wash require larger containers. The machine ensures that these products are filled consistently, making it a staple in the personal care industry.

4. Pharmaceuticals

In the pharmaceutical industry, precision and hygiene are paramount. The machine is used for packaging liquid medications and supplements into larger bottles or containers while adhering to strict cleanliness standards.

How to Choose the Right 1-5L Filling Machine for Your Business

Choosing the right 1-5L filling machine depends on various factors. Here are some tips to help you make an informed decision:

- Product Type: Consider the viscosity and flow characteristics of your product. Some machines are better suited for thicker liquids, while others excel at filling water-like products.

- Speed Requirements: Evaluate the volume of containers you need to fill each day. If you need high throughput, look for a machine that can operate at higher speeds.

- Budget: While the price is an important consideration, don’t compromise on quality. Look for machines that offer good value for your investment, with a solid track record of reliability and low maintenance costs.

Conclusion

The 1-5L filling machine is an indispensable tool for businesses that need to package medium-sized containers efficiently and accurately. Whether you are dealing with food, beverages, chemicals, or cosmetics, this machine provides the precision and versatility needed to optimize your production line. By understanding its features, benefits, and applications, you can make an informed decision about how to incorporate it into your operations. Investing in the right filling machine will not only enhance your production capabilities but also help your business maintain consistency, reduce costs, and meet the growing demand for high-quality products.