Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

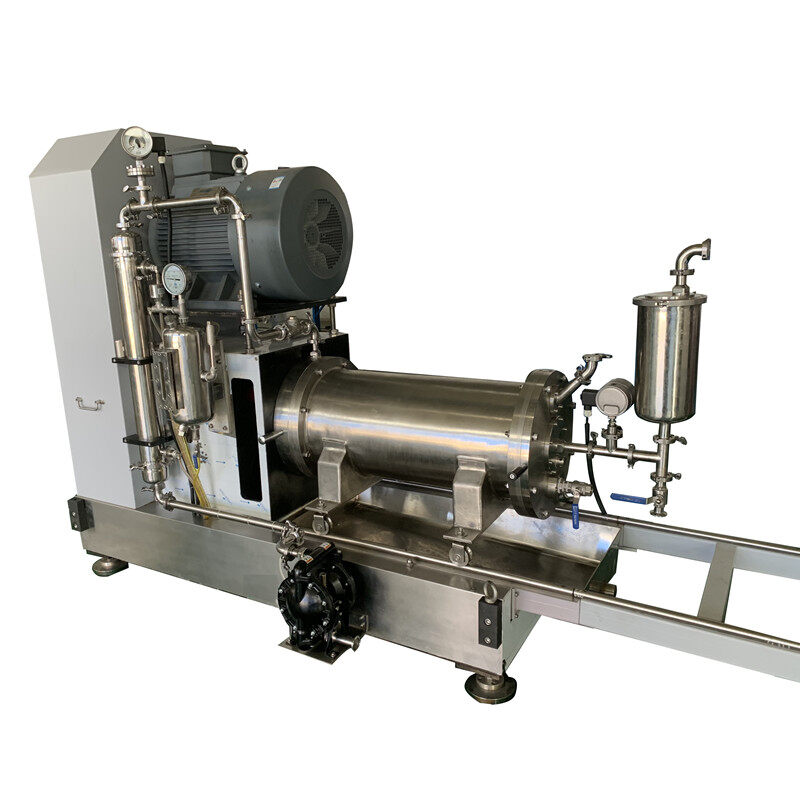

What Is a Bead Mill? Understanding the Key Technology in Material Processing

In manufacturing, good material processing is important for making high-quality products. One machine used for this is the bead mill. But what is a bead mill? It is a machine used for grinding and mixing materials, usually in liquids or slurries. This blog explains how it works, where it is used, and why it is important in many industries.

The Basics: What Is a Bead Mill?

A bead mill is a machine that grinds and disperses materials. It uses small round beads to move through a liquid. The beads are usually made of glass, zirconia, or steel. As the beads move, they create friction and break down large particles into smaller ones.

The bead mill works by using the energy of the moving beads. The beads break down larger particles, making them smaller and more evenly spread. This is useful in industries that need control over particle size.

How Does a Bead Mill Work?

A bead mill has a cylindrical chamber where the grinding happens. A rotor or agitator spins the beads quickly, causing them to hit the material. This action breaks down the large particles, making them smaller.

Parts of a Bead Mill

A bead mill has several parts:

- Grinding chamber: This is where the material and beads are placed.

- Rotor/agitator: This part moves the beads through the material, helping to grind it.

- Beads: These are the grinding media that hit the material and break it down.

- Discharge system: This part removes the finished slurry after grinding.

The bead mill works continuously. The material is always being ground and mixed.

What Are the Advantages of Using a Bead Mill?

There are many reasons why bead mills are used in many industries:

- High Efficiency: Bead mills can process large amounts of material quickly. This makes them good for high-volume production.

- Even Particle Size: Bead mills can make particles very small and even. This is important for industries like pharmaceuticals and cosmetics.

- Versatility: Bead mills can handle many types of materials, from thin liquids to thicker pastes. This makes them useful in industries like chemicals, food, and paint.

- Energy Efficient: Bead mills use less energy than other grinding machines, like ball mills.

Common Uses of Bead Mills

Bead mills are used in many industries where grinding and mixing are needed. Here are some common uses:

1. Paints and Coatings

In the paint industry, bead mills are used to grind pigments and mix them into the paint. This makes sure the color is even and the paint is smooth.

2. Pharmaceuticals

In pharmaceuticals, bead mills grind active ingredients to a fine powder. They also mix the ingredients into liquids like syrups and lotions.

3. Food and Beverages

Bead mills are used in food production to grind ingredients like cocoa in chocolate. They also help mix sauces and other products evenly.

4. Cosmetics

In cosmetics, bead mills help create smooth creams, lotions, and other products. The beads break down particles so the product feels smooth and works well on the skin.

5. Ink and Printing

In the printing industry, bead mills are used to make ink. They grind pigments and dyes to make the ink flow smoothly and have the right color.

Choosing the Right Bead Mill

When picking a bead mill, think about these factors:

- Bead Material: The type of bead (glass, zirconia, or steel) affects how well it grinds. Some materials are better for certain types of products.

- Viscosity of the Material: Some bead mills are better for thin liquids, while others work well with thicker materials.

- Particle Size: If you need very fine particles, use a bead mill with small beads and higher energy.

- Production Scale: Large factories often use continuous bead mills. Smaller operations use batch bead mills.

Maintenance and Care of Bead Mills

To keep a bead mill working well, do regular maintenance. Check the grinding beads, rotor, and chamber for damage. Clean the mill after each batch to avoid contamination.

Here are some tips for maintenance:

- Check the seals and moving parts for wear.

- Replace the beads when needed.

- Clean the chamber to avoid mixing different materials.

- Lubricate the moving parts as needed.