Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

What is a High Shearing Mixer?

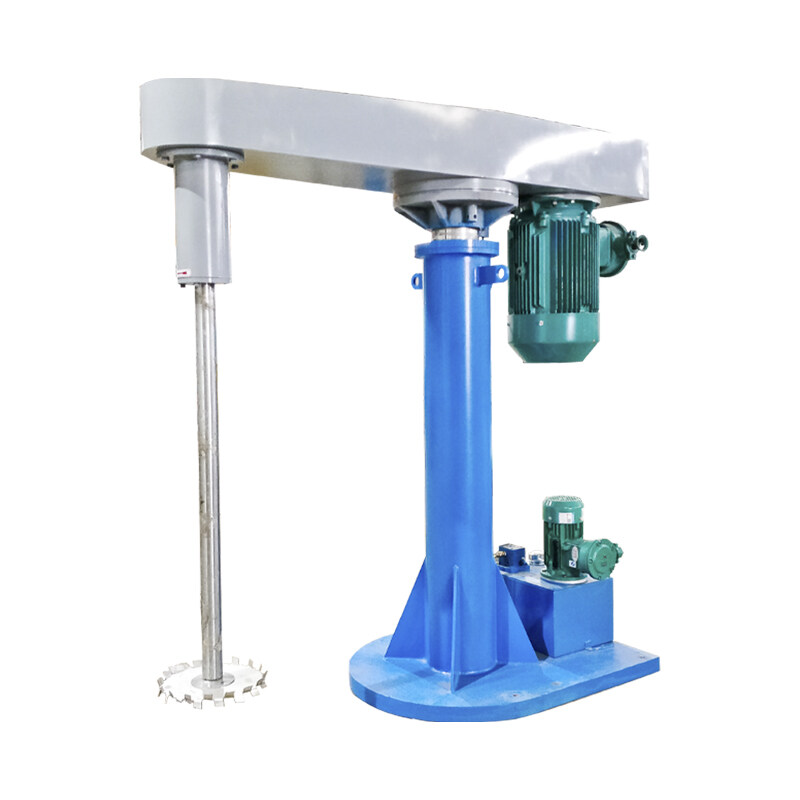

Multi functional high shearing mixer

The high shearing Multi functional mixer is a device designed to completely mix fluid, gas, and solid components that cannot be completely mixed by conventional methods. These devices use a hydrodynamic phenomenon called shearing strain to combine materials that are difficult to mix. Shearing strain occurs when two fluids move with each other at different velocities, producing a deformation region along the contact region between them. The high shearing Multi functional mixer uses a series of high-speed impellers rotating in a fixed housing to effectively mix a component that is introduced into another component shunt at different speeds. There are several types of commonly used shearing mixers, including intermittent, pipeline, and ultra-high shearing mixers.

A combination of materials that will not mix completely under normal conditions is called an immiscible mixture. Oil and water are a good example of this usually incompatible element pair. However, thorough mixing of often incompatible fluids, and solid and gas combinations is an essential component of many industrial and chemical processes. When the conventional combination method fails, the high shearing Multi functional mixer can be used to realize the complete mixing of the originally immiscible components. These Multi functional mixer utilize a hydrodynamic mechanism called shearing stress, which occurs in the area where two materials moving at different speeds are in contact with each other.

The shearing stress will cause the local deformation of the two material flows so that they are strongly combined along the shearing plane. In high shearing mixers, this effect is usually achieved by a high-speed impeller or rotor rotating in a tightly fitted static shell or stator. The part material introduced into the chamber of the stator will undergo a higher rotation speed at its outer edge than at its center. This velocity difference results in the shearing stress required to effectively bond the material. These combinations may consist of different fluids, fluids, and gases or fluid and solid pairs, and their resulting mixtures are called a lotion, sol, and suspension, respectively.

Several different types of high shearing high shearing mixer are commonly encountered in the food processing, pharmaceutical, cosmetic, and paper industries. These include batch, series, and ultra-high shearing mixers, each with specific operational advantages. The intermittent mixer is characterized in that the mixing tank is located at the bottom of the impeller, and the top of the impeller is equipped with component materials, which can quickly process a large number of materials. The online mixer is particularly suitable for mixing fluid/powder combinations and has a linear inlet / outlet device that attracts and mixes the mixture. Ultra-high shearing mixers usually allow one-way mixing and have a series of perforations in the stator through which the material can be extruded at high speed.

How to distinguish a high-speed disperser from a high shearing mixer?

The dispersing machine is mainly used for solid-liquid materials, which means that the solid particles are mechanically decomposed and dispersed in the solution, and the dispersing tools such as the dispersing disk are used to achieve the ideal dispersing effect. High speed dispersing machine is a kind of equipment mainly used for crushing, dispersing, emulsifying, and mixing liquid raw materials with different viscosities. It operates at high speed through different types of dispersing discs, and performs high-speed and strong shearing, impact, crushing, and dispersion of materials, so as to achieve the functions of rapid mixing, dissolution, dispersion, and refinement.

For liquid-liquid materials, the mixer uses high shear force to mix one liquid with another immiscible liquid. The rotor-stator system should be used to achieve the effect of high-efficiency emulsification. It is suitable for low viscosity products. The high shear emulsifying machine quickly and evenly distributes one or more phases into another continuous phase and makes use of the strong kinetic energy brought by the machinery to make the materials bear hundreds of thousands of hydraulic shears per minute in the narrow gap between the stator and rotor. Centrifugal extrusion, impact, tearing and other comprehensive effects can instantly and evenly disperse and emulsify. After high-frequency cycling, we can finally get fine and stable high-quality products without bubbles.

Searching for a high shearing mixer, Multi functional mixer, lotions mixer from China, you can get high-quality products at a nice price.